A masonry chimney is comprised of several parts and it is not as simple as you might think it is. And if a chimney professional just informed you that your chimney needs relining, it might seem to be confusing.

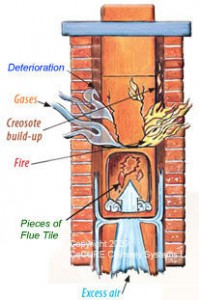

To fully understand why chimney relining is important, you must first understand the anatomy of your chimney. From outside to inside, there is the brick, the airspace, the mortar joints, the flue liner, and the crown. The flue liner seals the inside of your chimney and prevents toxic gases, smoke, and other dangers from escaping from your chimney rather than being channeled outside.

To fully understand why chimney relining is important, you must first understand the anatomy of your chimney. From outside to inside, there is the brick, the airspace, the mortar joints, the flue liner, and the crown. The flue liner seals the inside of your chimney and prevents toxic gases, smoke, and other dangers from escaping from your chimney rather than being channeled outside.

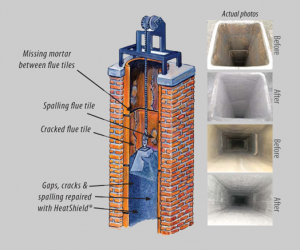

A proper chimney inspection will need to be performed by a professional chimney sweep if your chimney has any issues and needs relining. These are just a few reasons that a chimney needs to be relined:

- Gaps Between Flue Tiles

- Cracked Flue Tiles

- Flaking Flue Tiles

Dangers Of Not Having A Flue Liner

- Loss of Efficiency

- Blockages

- Fire Safety

- Health Ricks

These are just a few of the reasons and dangers that emphasis the need for a professional inspection, evaluation, and repairs if needed. The Chimney Safety Institute of America’s website, provides a good source of information for homeowners who may not be familiar with the construction and purpose of chimneys and liners.

Types of Liners

There are many types of liners available. The HeatShield® liner offers many advantages over other types of flue liners. First, HeatShield® has been approved for use in all types of chimneys and heat sources. As stated on their website, “As a repair, (HeatShield®) has been proven to withstand moisture, corrosive flue gases, and temperatures in excess of 2900°F. It’s rated a “Super-Duty” refractory mortar per ASTM (American Society for Testing and Materials)C199. It surpasses both National Fire Prevention Association (NFPA) and International Residential Code (IRC) which require only a “Medium-Duty” refractory mortar for use in fireplaces and chimneys.

Metal liners are also used in relining and may be made of stainless steel, aluminum, galvanized iron. However, the HeatShield® seals well, is long lasting, and virtually impervious to heat making your home even safer.

The HeatShield® Process

When you and your chimney professional decide the HeatShield® process is best for you, there is a multi-step process that “takes the heat, so you don’t have to”:

An application plug is placed at the bottom of the flue and attached to a winch at the top of your chimney, so a coating of HeatShield® Cerfractory® sealant can be applied to the flue walls.

An application plug is placed at the bottom of the flue and attached to a winch at the top of your chimney, so a coating of HeatShield® Cerfractory® sealant can be applied to the flue walls.- A custom fitted “CeCure”® sleeve is lowered into the chimney and attached to the top of your chimney and pressed into the first coating of the HeatShield® Cerfractory® and temporarily clamped into place.

- Another coating of HeatShield® Cerfractory® is applied over the sleeve.

- A video camera will be used to verify the coating is complete..

Due to the serious function your chimney serves in protecting you from fire, smoke, and toxic gas hazards, it’s important for you to take chimney maintenance seriously and correct any problems as soon as possible with a trained profession.

If your chimney needs an inspection or relining, contact the experts at Total Chimney Care to schedule an appointment.